|

NEEDLE RETAINER ASSEMBLY |

|

|

RTL needle retainer assembly is a kind of independent bearing unit with

high load capacity and rigidity especially applicable for the tray of

shaft and seat holes with the unit which is limited in radical dimension. Each needle have excellent operative characteristic due to each needle exactly guided and kept by the retainer.

|

|

Structure |

|

K |

Needle retainer

assembly |

|

K...ZW |

Double row needle

retainer assembly |

RTL needle retainer assembly is divided into two series : single row and double row. In the

case of crank shaft where difficulty of using and mounting occur , RTL will supply the divided

structure.

In general case, M type punched retainer is used, besides, there are metal solid retainer,

fiber glass reinforced nylon 66 retainer. The latter can work under the temperature of 120℃ for

a long period while it can even operate under 150℃ for short time.

|

Precision |

The dimensional tolerances of RTL needle retainer are listed in Table 1 . When bearings of more

than two types are used in parallel on a same shaft , the needles must belong to the sub group with

same value. The retainer width tolerance Bc is -0.2/-0.55mm.

Table 1 needle diameter tolerance

|

Precision

grade |

Needle

diameter tolerance |

||

|

G2 |

0~-2 |

-2~-4 |

-4~-6 |

|

G3 |

0~-3 |

-3~-6 |

-6~-9 |

|

Combination |

The radical gap of RTL needle retainer assembly depends on the machined precision of the inner and outer trays

and the needles. Table 2 shows the combination recommended as per the different operational conditions. Table 2 the recommended shaft tolerances of the casing when

machined as per G6

|

Operational

conditions |

Recommended shaft tolerance |

|

|

≤80 |

>80 |

|

|

High speed, high precision |

j5 |

h5 |

|

General operational condition |

h5 |

g5 |

|

High temperature or greatmounting tolerance |

g6 |

f6 |

When the needles are running directly in the shaft or in outer case, to make the needle retainer assembly reach its fully load capacity , the hardness of the inner and outer tray surface must reach 58-62HRC and the roughness must not greater than 0.32μm . the surface quality must be the same of rolling bearing tray.

|

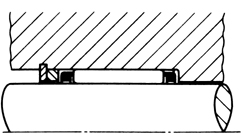

Assembling and relative dimensions |

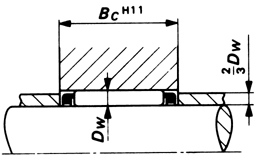

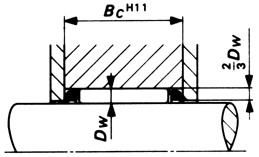

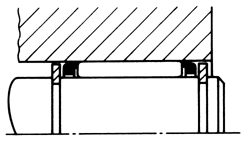

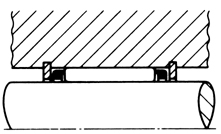

Figure 2, Figure 3 show the relative dimensions of the needle retainer assembly. The axial fixed way

used in bearing assembling is show in Fig 4 and 6. When used for high speed, a heat treated washer should

be added between the retainer and the axial limit so that direct contact of retainer and limit can be avoided

|

图1 |

图2 |

||

|

图3 |

图4 |

图5 |

|